As a stained glass panel outer frame, a brass frame is popular, however, an aluminium frame is also convenient and strong. Especially, it matches well with a modern design panel. But, if you don't cut and hole it right, it will be bent. Right way is as below.

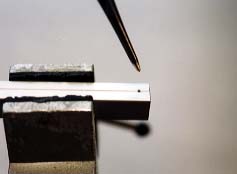

an aluminium frame bar with a screw-hole inside. figures in

millimeter.

Nine mm inner width suits lead came panel thickness. The bar is

180cm long. For copper foil panels, it is recommended to insert

gum-tube or putty as filler.

You assemble cut bars as above. In order to decide each length of a frame easily and accurately, at first, put aluminium pieces of bar to left and right sides deciding length "a" , then put cut "a" bars to up and down sides deciding length "b".

All is completed by this, easy made without any soldering.

It is also easy removed.

You may spray lacquer to change the aluminium color.

(maker: ROUAULT STUDIO patent-p)

![]() There is a narrow type aluminium

bar for a copper foil panel. Please click here.

There is a narrow type aluminium

bar for a copper foil panel. Please click here.