6. Traditional Industry in Japan

Japan Steel

@29/May/2005

RSS Eurasia Club/JICA SV in RSS Amman Jordan

[Purposes] [Coordinator Office] [Schedule] [Materials] [Top]

1. Abstract:

Japan steel is known worldwide in the form of Japanese sword that is feather

light and magic sharp edged. This extraordinary steel has long been developed

in Japan with craftsmen's perpetual effort

to improve the quality with endless repetition of the new trial. Japan

was also given two other important materials that are extremely important

to produce that high performance steel. One is law materials known as

iron sand that contains rich

and high quality crystal oxide iron in it. The other

materials is whetstone, we call it "toishi"

in Japanese. Steel edge is sharpened in three stages.

Each sharpening stage, rough, middle and fine, different kind of whetstone is used.

There are so many kind of whetstone in the world.

But nowhere in the world, these three whetstone found yet in one place except in Japan.

Extremely sharp edged Japan sword is made with these three elements and

craftsmen's perpetual effort of endless improvement of the quality.

Today, this technique is brushed up into the

state of art technology and applied to the many important part of modern industry

like aircraft,

tunnel boring machine, kitchen knife and etc.

Japan Sword that is extremely light and sharp edged

89

2. Three Elements produced Japan Steel:

Japan, from the old age, suffered of lack of law materials like iron ore,

oil, coal and etc. Japanese people had been directed to use the materials

to its maximum level without wasting a bit and piece. Because of this resource

limitation, our ancestors had long developed shrift Japanese mind that

at all time maximize its use as much as possible. Craftsmen are always

highly respected by the people, therefore, they perpetually made their

best effort to develop their skill and ability toward higher level in order

to supply better products and services to the people. This attitude of

the people is one of the key elements among three.

Though Japan is not rich in iron ore, but relatively high quality and enough

amount at that time, iron sand was found many part of Japan. Iron sand

is black colored crystallized oxide iron that reflect the light and shining

under the sun. Probably because Japan is country of abundant active volcanic

mountains all over, high quality iron sand is given to the surface. This

black shining heavy sand should have attracted our ancestor in great concern.

Soon after, they should have learned that this sand can be made for excellent

weapon of light weight, strong and sharp. This high quality iron sand was

the second element of the Japan Steel.

Iron sand: Crystallized Oxide Iron

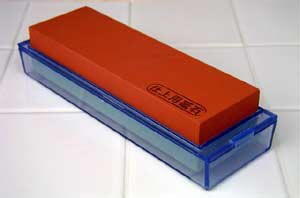

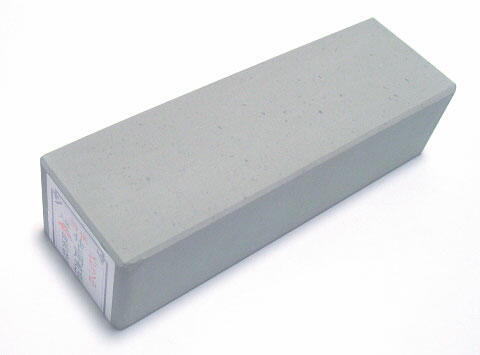

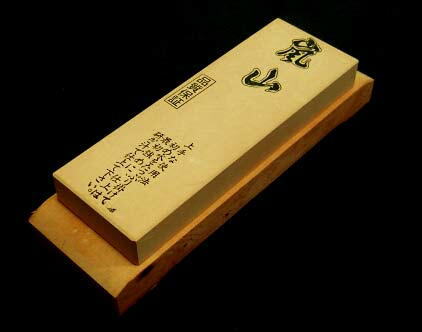

The third element of fine Japan steel was whetstone. Japan sword is specially

characterized of its sharpness. This sharpness has only been accomplished

with very fine whetstone that has ever been found only in Japan among the

world. Nakayama in Kyoto, ancient capital of Japan, extra fine whetstone

layer found. Over a thousand years, craftsmen of Japan sword had used this

whetstone to sharpen his sword or knife. This extra fine whetstone had

been formed from the dead body of microorganism in approximately 250 million

years ago. That fineness of the whetstone has never been found anywhere

in the world except Nakayama Kyoto. Today, artificial whetstone are widely

used in the worldwide. But none is superior yet than the natural fine whetstone

of Nakayama Kyoto.

90

Three different grade whetstone, rough, medium and fine grade

From these three elements, extra fine and sharp Japan Sword had been made

in Edo period, three to four hundred years ago, and regarded as art items

today among the world collector

91

Details of ornamental decorations of Japan Sword

3. Application to the modern world:

After long history and continued improvement of Japan Steel, it becomes

one of the finest steel in the world. Today, Japan is supplying special

high quality steel to the various important industry in USA or Europe.

One of the example is turbine blade of latest high power jet engine. Jet

engine produces more power in smaller size if the fuel burning temperature

is increased. Therefore, Turbine blade durable in the higher temperature

is much desired in designing latest model of high power engine. Major US

aircraft manufacturer is using Japanese made special anti-heat steel as

turbine blade for their latest model jet engine.

92

Japan steel is used in its turbine blade

Another example is tunnel boring machine used for Dover Tunnel (Euro-Tunnel) that had long been dream over few hundred years. This dream never become true because of difficulties of digging cement-like rock under the channel. No TBM (Tunnel Boring Machine) could dig that easy become cement-hard rock during boring until Japanese cutting blade head introduced into the digging machine in 1987. Kawasaki Heavy Industry introduced their extra large sized and state of art TBM (Tunnel Boring Machine) in digging the tunnel. It took only 4 years to complete the digging 20 km span continuously round the clock under the sea water. The cutting head had fitted extra hard Japan Steel.

TBM (Tunnel Boring Machine) Kawasaki Heavy Industry used for Euro-Tunnel

93

Next example is kitchen knife. Solingen, a Germany town is world famous

where series of high quality knifes are produced. For centuries, maisters

of knife had been manufacturing strong, easy to handle and real sharp knife.

But few know that Japan steel is used for those knife blade. Today, one

of the major manufacturer of kitchen knife in Solingen, Henckels moved

its main plant from Solingen Germany to Gifu Japan, and whole process of

kitchen knife of the company took place in Japan.

More and more Chef of the famous restaurant in New York are now using these kitchen knifes made in Japan

that has good reasons to be choose, good design, light weight and extra sharp cutting taste.

Extra-hard and sharp Kitchen knife: Twin Cermax M66, German Brand but made

in Japan

Over 50% of razor blade of the world demand supplied by Japan

94

The last example of today is piston rings and engine valves.

These important parts for vehicle engine requires very high performances in very high temperature.

Extra high quality Japan steel is gain used as materials for these parts.

Japan is no.1 supplier of these parts in the worldwide.

Piston Rings and Engine Valves of majorities of vehicles are made from

Japan steel

| [Coordinator Office] [Purposes] [Schedule] [Materials] [Top] |

| [Back to Page Top] |