7. Railway System in Japan

Shinkansen

@27/Jul/2005

RSS Eurasia Club/JICA SV in RSS Amman Jordan

[Purposes] [Coordinator Office] [Schedule] [Materials] [Top]

1. Abstract:

Japanese Railway System is almost mystically believed of its punctuality in extreme dense packed traffic. Japan has developed its railway system into state of art standard of efficiency and safety in order to handle the demanding traffic in densely populated metropolitan area like Tokyo and Osaka. This tradition to keep punctuality become heavy burden for the train operating company and its workers. Time table of the train traffic becomes more and more congested. In some cases, every scores of seconds, another train depart from the same platform. That requires extra stress to the train driver to keep the time table in as short as seconds. Delay of the train for few tens of seconds usually does not considered in anywhere in the world except Japan. Today, railway in Japan stretches 32,674km throughout Japan, carrying 60 million people each day.

In 1950s, the train system was losing its interest by travellers in every

part of the world. Because of its limited mobility, comfort and speed.

Short distant travellers prefer automobile and long distant travellers

prefer airplane than taking train. However, in this adverse worldwide trend,

Japan had developed high speed train system and put it into operation by 1964, commemorating the Tokyo Olympic Game. Decision of building the high speed train system, and very short period of development and construction in 5 years of 552km long Tokaidou-Shinkansen Line was really unique and admirable

achievement.

So called bullet train was really innovative that no one in Europe and USA could expect the realization such high speed train at that time Targeted and achieved speed of the train was more than twice the speed of the conventional fasted train in Japan. Fastest conventional train at that time travels in 95km/h, instead the Bullet Train travels in 210km/h all the way. This success of high speed train made renaissance of high

speed rail way transportation era in the western countries like France

and Germany in short period They changed their mind that train is still

useful for mass public transportation.. Thus, French TGV, German ICE was built after the success of Shinkansen(Bullet Train) in Japan.

Shinkansen (MAX Yamabiko)

2. Technologies used in Shinkansen:

Dozen of new technologies are used in Shinkansen to achieve its targeted speed, passenger's comfort and safety. Those are;

_____1. Long rail: 1.5 km rail instead of 25m conventional

_____2. No crossing (All exclusive or elevated track)

_____3. Air tight Body (Avoid rapid pressure change in Tunnels)

_____4. Anti-vibration by Air Spring

_____5. No signal on the track, but on Driver's Seat

_____6. CTC (Centralized Traffic Control) controls all traffic

_____7. Anti-collision System keeps train 3km or more at all time

_____8. Fed by AC 25,000 V instead of conventional DC 1,500 V

_____9. All Motored Car with newly developed extra quiet motors

____10. Half size Pantograph reduced air resistance

____11. Placed Emergency Stop Switch every 250m along the track

____12. Earthquake Detection System stop feeding on detecting the quake

2.1 Long Rail:

Conventional rail is approx. 25 m long, instead, Shinkansen uses long rail

of approx. 1.5 km. So that annoying click sound is greatly reduced in order

to secure comfort of travellers. Further more, at connection part it employs

gap-less sliding cut shown in the figure below.

Joint Section of the Long Rail

2.2 No Crossing (All exclusive or elevated Track):

Tracks for Shinkansen were newly constructed as exclusive use, and in all

metropolitan area, elevated tracks are used in order to secure the safety

for other transportation means and trespassers. Specially designed fences

are installed on the platform of Shinkansen Railway Station to prevent

accident that people collides with passing train on its maximum speed even

in the premises of the station.

Exclusive use tracks, or in metropolitan area all tracks are elevated

2.3 Air-tight Body:

Due to geographical landscape that Japan has, railway track should have

many tunnels through its line. When high speed train got into the tunnel,

air pressure rapidly changes and passenger suffer sever uncomfortable ear-ache

every time the train passes the tunnel. In order to avoid such suffering,

the body is made air-tight design similar to airplane, so that the air

pressure is kept constant whenever the train passes the tunnel.

Interior of Shinkansen passenger car

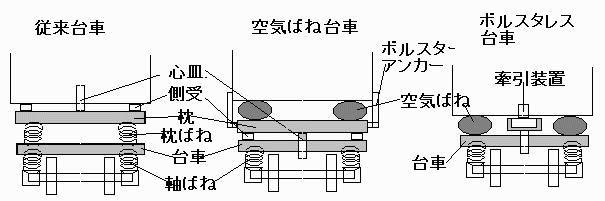

2.4 Anti-Vibration of the Body:

When the train travel in high speed, the body starts shaking, and in the

worst case, it would be disintegrated. To prevent this body vibration,

air spring was newly developed to be installed in all car. Smooth and quietness

in the passenger car is achieved. Improvement of this technology is ever

developed and implemented into the passenger car, so that travellers can

enjoy quieter and smoother passenger car year by year.

Above drawings shows very simplified principle of air spring. Today, this

air spring is highly developed and modified, and transformed into active

suspension system which control position of whole body and individual passenger

seat against bending G and horizontal/vertical vibration of the passenger

car.

2.5 No signal post on the track but on Driver's Seat:

Since the Shinkansen travels at high speed of 270km/h or more, the driver could not see the ordinal signal posted on the signal post along the track. So that no signal post is place along the track, instead all necessary signal are displayed on the driver's seat. The signal is sent from CTC (Centralized Traffic Control Center) via railway.

All necessary signals are displayed on Driver's Seat, but no signal along

the track

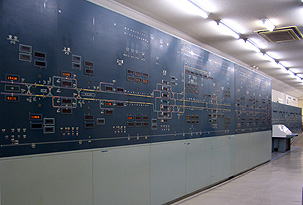

2.6 CTC (Centralized Traffic Control System) controls all traffic:

Because of the safety is the most important factor in the high speed train

system, Central Traffic Control System (CTC) is newly developed and introduced.

Ordinal control system by communicating central controller and train driver

could not work in high speed train system due to shortage of time to judge

the necessary action and convey it to the train driver in time.

CTC old (Left) and new (Right)

CTC in the beginning was displayed on a large wall-type display, but today,

it is displayed in more compact and advanced PC display.

2.7 Anti-collision System:

One of the safety measures taken is anti-collision system. This system

works to keep train distance 3km or more at any time. When the train approaches

other train and its distance becomes 3km, the system automatically reduces

the speed of the train down to 30 km/h and the tragic collision accident

shall be prevented.

2.8 Fed by AC 25,000 V:

Conventional train is fed by DC 1,500 V, instead Shinkansen is fed by AC

25,000 V in order to reduce the construction cost of feeding line along

the railway track. In higher voltage, thinner feeding line can be used.

As for the car design, using higher voltage can reduce the total weight

and increase the speed. Only two Pantograph are necessary in one whole

train which greatly reduce the air resistance and air cutting noise. Thus

it contributes to the environmental friend design as well.

One arm Pantograph: only two pantographs are necessary for one whole train (8 to 16 cars)

Shape of the pantograph is designed aerodynamically, and reduced air cutting

noise in minimum.

2.9 All car has Motors:

It was long legendary concept that the long-distance passenger car is pulled

by heavy locomotive(s) in order to secure quietness and give comfort to

the passengers. Idea of all motored car in luxurious long distance passenger

car was unprecedented. But Japanese railway engineers reached their conclusion

that all motored car is the solution to raise the speed more than twice

than that of the maximum speed of that time. Engineers had believed that

breakthrough could be made to reduce the mechanical noise of motor to the

level of normal saloon car even before they start research and development.

By putting motors in every car, weight of maximum load to the railway track

greatly reduced and construction cost and delivery time of the railway

track had reduced tremendously.

No locomotive but all car has motors

2.10 Half Size Pantograph:

Size of the pantograph has been reduced in half compared to the conventional

type, so that the air resistance and air-cutting noise had been reduced

considerably. This was achieved by constructing exclusive railway track

for Shinkansen,. the distance between the pantograph and feeding line can

be kept in certain figure at any speed that Shinkansen travels.

2.11 Emergency Stop Switch is located at every 250m along the railway track:

In order to secure maximum safety measures, emergency stop switch is installed

at every 250 m along the railway track from the beginning of the line to

the end of the line.

2.12 Earthquake Detection system stop Feeding:

Japan is earthquake rich country. Anti-earthquake system is indispensable

for mass high speed transportation system. In this sense, earthquake detection

system had been developed and put into operation as one of the safety measures

of Shinkansen. When the system located most close to the epicenter detects

P-wave of the earthquake, and it automatically cuts the feeding to the

Shinkansen and stops the train immediately before the S-wave reaches to

the train.

| [Coordinator Office] [Purposes] [Schedule] [Materials] [Top] |

| [Back to Page Top] |